What are the advantages of the ZF torque converter?

Automatic transmissions have all but made the manual gearbox obsolete.

From small economy cars, all the way to huge earth-moving haul trucks, the popular choice and often times the only choice is automatic transmissions.

One of the main contributing factors to this has been the improvements in the efficiency of torque converters.

Since the introduction of modern torque converters in the 1950s, they have been steadily gaining traction on the efficiency of that of manual clutch-operated motor vehicles. A major leap was made, however, with the introduction of the lock-up clutch. This design makes use of a clutch disk or multiple disks that engage and disengage when necessary. These clutch disks lock the impeller and turbine side of the torque converter together. This results in the locking of the engine speed to the transmission input speed and is done when both speeds are almost equal. This eliminates the losses that take place in the torque converter at cruising speeds.

Today’s transmissions are more efficient and reliable than any manual gearbox setup on the market today. The ZF transmissions and torque converters line-up are impressive feats of engineering that offer many benefits and advantages. This article will, however, focus on the ZF torque converters.

The ZF torque converter boasts an impressive list of advantages over conventional torque converters. These include:

• Up to 6% reduction in fuel consumption of motor vehicles

• Improved noise insulation

• Increased transmission life due to less wear

• Increased driver and passenger comfort

Let us take a look at how ZF goes about bringing these advantages to life.

What makes the ZF torque converters a cut above the rest?

As a motor vehicle owner or operator, it would be wise to invest in equipment that provides greater long term value with ease of operation, fewer maintenance requirements, and better comfort. This is what is promised with the use of the ZF torque converter.

ZF is a Germany based company that specializes in motor vehicle technology.

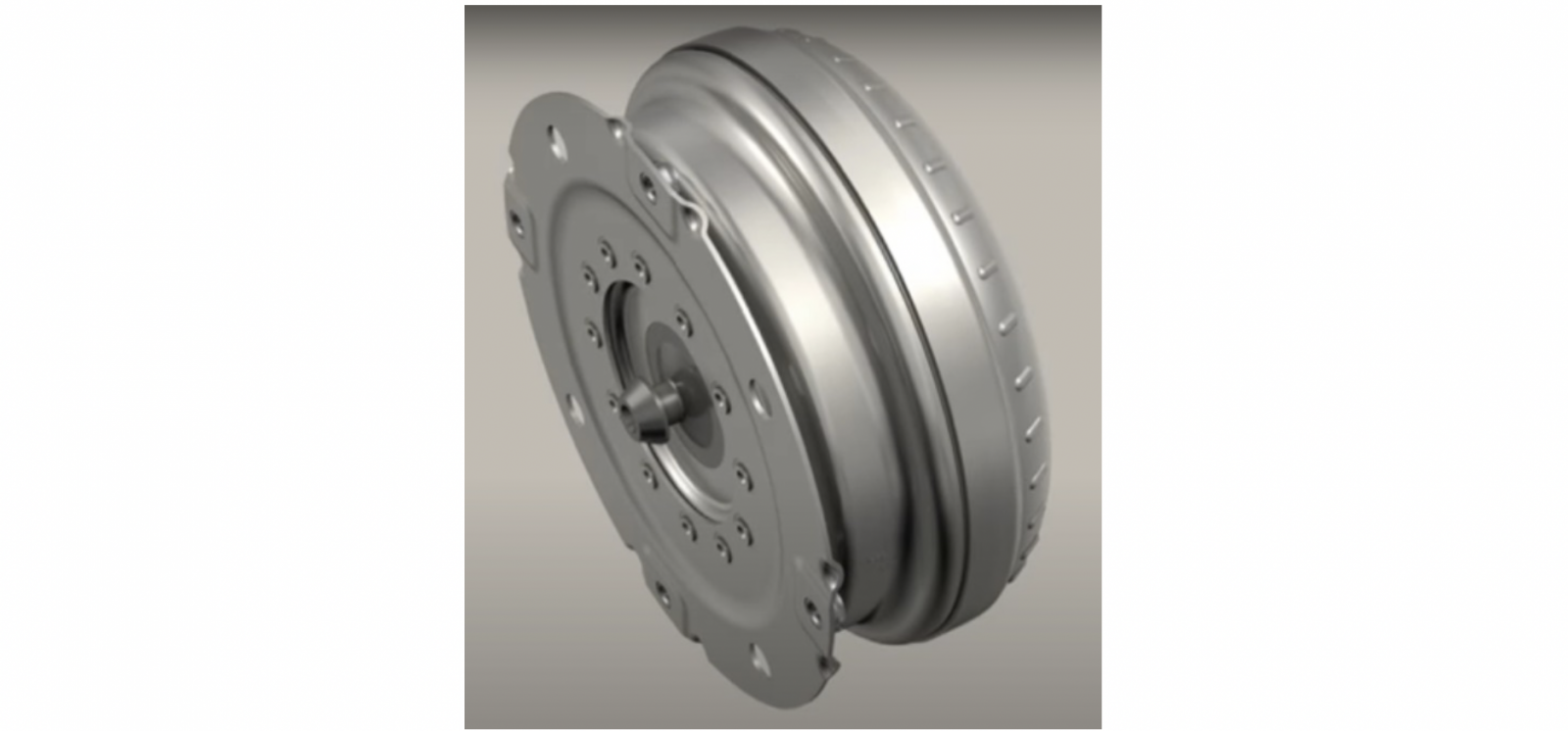

Their ZF torque converter has been a game-changer since its introduction. The hydrodynamic process that results in the torque multiplication and transmission has been fine-tuned and regulated by the company to result in higher performance efficiency. Years of scientific research, testing, and investments have allowed ZF to find the right materials for each component that makes up their torque converters. They have also invested in finding the right impeller, stator, and turbine vane sizes and angles to create maximum torque multiplication and transfer. The result is a high performance and low inertia torque converter suitable for a wide range of applications.

The standout physical components of the ZF torque converter are the multi-disk lockup clutch and the torsional vibration damper with its spring sets.

The Torque Converter Lock-Up Clutch

The multidisc lockup clutch creates a rigid connection between the impeller and the turbine rotor at a speed predetermined by the vehicle manufacturer. The locking of the clutch discs stops the hydrodynamic process that usually takes place within the torque converter. This, therefore, eliminates the hydrodynamic losses that usually occur. This purely mechanical connection between the engine and the drivetrain results in the transfer of maximum efficiency.

During lockup, however, the damping effect of the hydrodynamic circuit is also eliminated. This has the adverse effect of introducing additional vibration and noise into the drivetrain assembly. Fortunately, ZF has a solution for this resulting issue: the torsional vibration damper.

The Torsional Vibration Damper

The torsional vibration damper absorbs the vibrations generated by the direct coupling of the engine and drivetrain during the locking of the clutch. The absorption of these vibrations leads to lower noise levels, and reduced wear and tear on the parts in and surrounding the drivetrain.

The torsional vibration damper absorbs the vibrations generated by the direct coupling of the engine and drivetrain during the locking of the clutch. The absorption of these vibrations leads to lower noise levels, and reduced wear and tear on the parts in and surrounding the drivetrain.

This additional component also allows for the lockup process to take place earlier than on conventional torque converters. This greatly improves efficiency as the transmission does not have to shift down as often to a lower gear. The transmission can even shift up earlier than with traditional torque converters. This ability to shift up earlier improves vehicle fuel efficiency by up to 6% according to the reports of ZF. There is also the added benefit of comfort due to noise and vibration reduction.

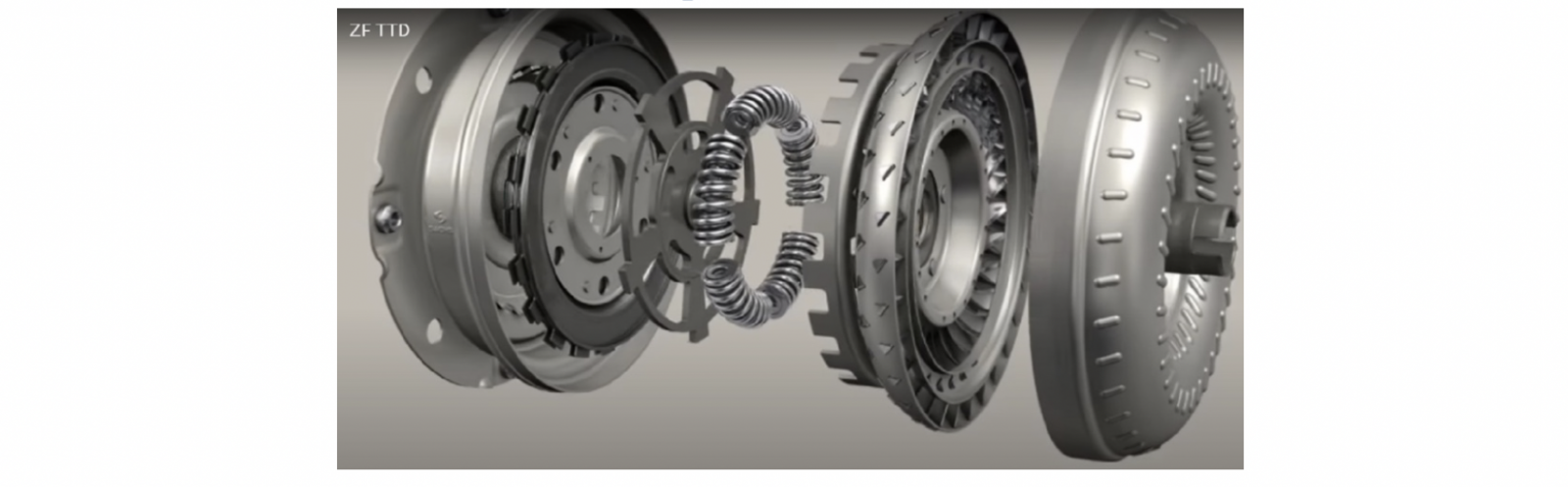

There are two variations of the torsional vibration damper ZF clutch: Turbine Torsionsional Damper (TTD) and Twin Torsional Damper (Twin-TD)

The TTD consists of six springs arranged in a circular formation on a circular plate. These dampen the torsional vibrations during operation.

The TTD consists of six springs arranged in a circular formation on a circular plate. These dampen the torsional vibrations during operation.

The Twin-TD consists of twelve springs arranged in two circles, one inside the other, on a circular plate. These springs perform the same job as the single spring set version.

The use of either of these torsional vibration dampers solely depends on the specific drivetrain that it is being used on.

When Should You Choose a ZF Torque Converter?

There is no wrong application for choosing to use a ZF torque converter.

The advantages explained are ideal for both high speed and high torque vehicles.

The early lock-up and vibration damping capabilities of the clutch make it ideal for improving efficiency on the freeway. You will, therefore, enjoy more mileage and comfort in your red topless sportscar.

The low inertia and early shifting capabilities make it great for frequent start and stop, as well as load-bearing vehicles such as a forklift working in a confined factory or the city bus that’s always stuck in traffic.

Written by: Alshane Brown / BuyAftermarketParts